👇CHEST COVER FREE DOWNLOAD👇

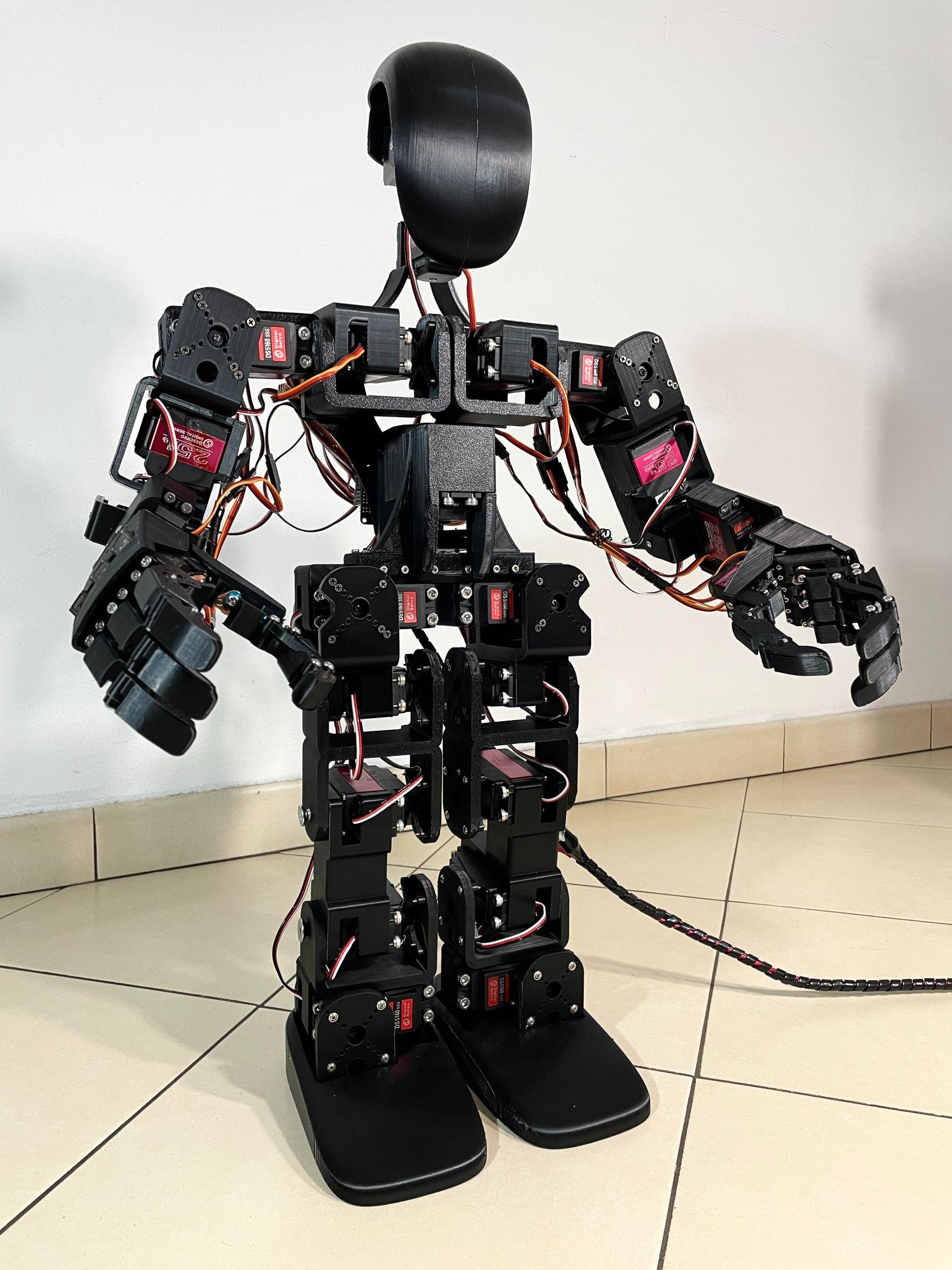

AFTER MORE THAN 10 YEARS OF RESEARCH AND DEVELOPMENT, WE ARE PROUD TO PRESENT TO THE WORLD AN INNOVATIVE AND AFFORDABLE SOLUTION THAT COMBINES ADVANCED TECHNOLOGY AND LOW COST

WE HAVE SPENT YEARS IN THE PERFECTION OF EACH AND EVERY MOVEMENT TO GIVE OUR ROBOT FLAWLESS BALANCE, SYNCHRONIZATION AND EQUILIBRIUM. WE OVERCAME SEEMINGLY INSURMOUNTABLE CHALLENGES TO REALIZE A DREAM THAT HAS NOW BECOME A REALITY

A REVOLUTIONARY EXPERIENCE THAT TRANSFORMS THE CONCEPT OF ROBOTICS FROM THE PAGES OF SCIENCE FICTION TO TANGIBLE REALITY. GET READY TO CROSS ALL BOUNDARIES AND EMBRACE THE FUTURE WITH YOUBIONIC X3

IF YOU ARE LOOKING FOR A NEW WAY TO EXPLORE THE POTENTIAL OF ROBOTICS, YOU HAVE FOUND THE RIGHT PLACE. YOUBIONIC X3 IS THE PERFECT PLATFORM TO EXPLORE, LEARN AND CREATE WITH ROBOTICS TECHNOLOGY IN AN ACCESSIBLE, EDUCATIONAL AND INNOVATIVE WAY

THE DREAM OF HAVING YOUR OWN HUMANOID ROBOT HAS NEVER BEEN CLOSER. WITH THE ABILITY TO PRINT AND ASSEMBLE ROBOTS USING LOW-COST COMPONENTS, YOU CAN SAVE SIGNIFICANTLY COMPARED TO BUYING ALREADY ASSEMBLED ROBOTS. GAIN SKILLS TO GET HIRED BY LARGE ROBOTICS COMPANIES OR TO LAUNCH YOUR OWN SUCCESSFUL STARTUP IN THIS FIELD

DISCOVER THE LATEST FRONTIER IN HUMANOID ROBOTICS: AN AMAZING COMBINATION OF INNOVATION, FLEXIBILITY AND POWER. YOUBIONIC X3 OFFERS AN UNPRECEDENTED EXPERIENCE FOR ENTHUSIASTS, STUDENTS, AND PROFESSIONALS LOOKING FOR ADVANCED AND AFFORDABLE SOLUTIONS

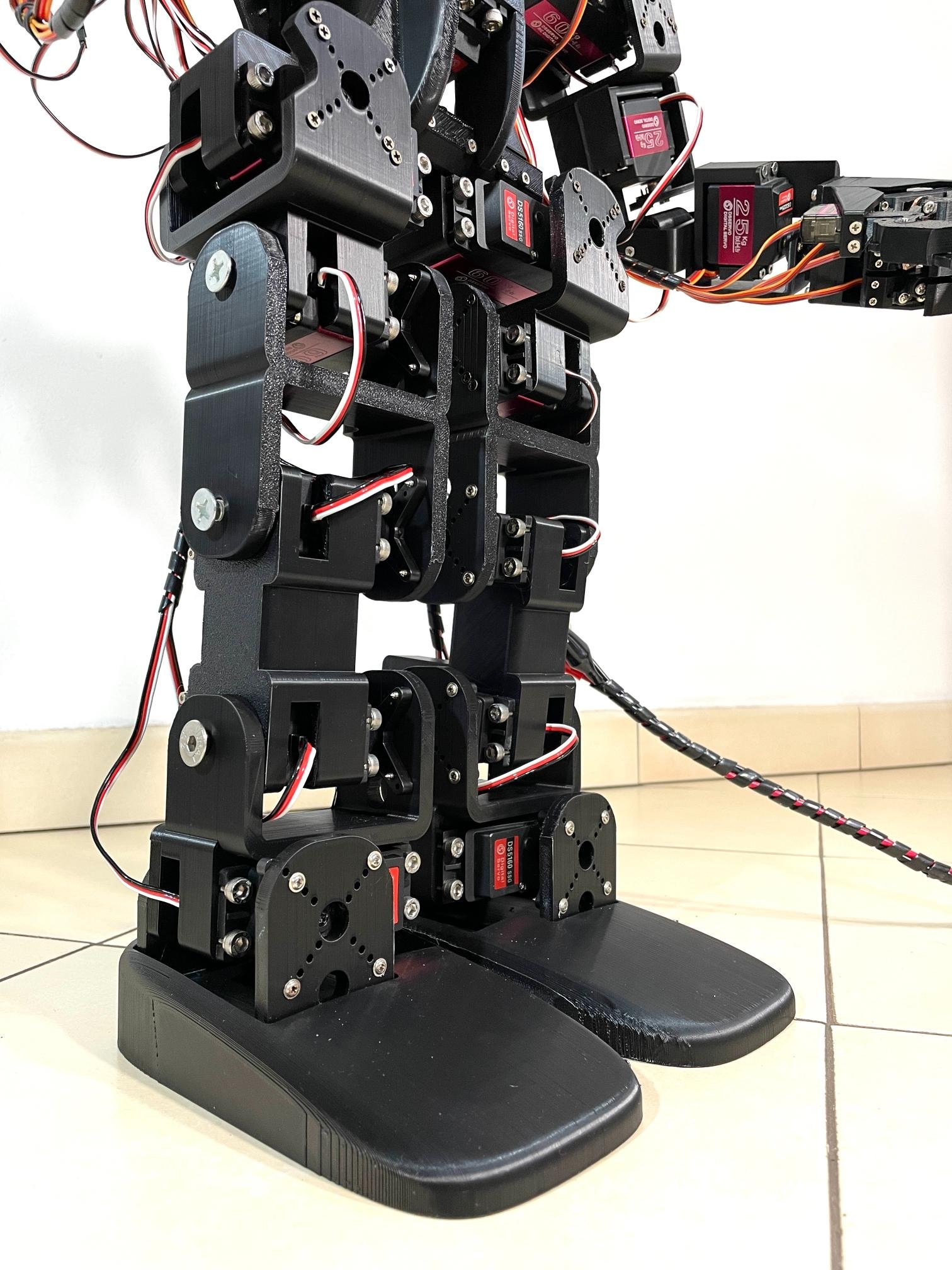

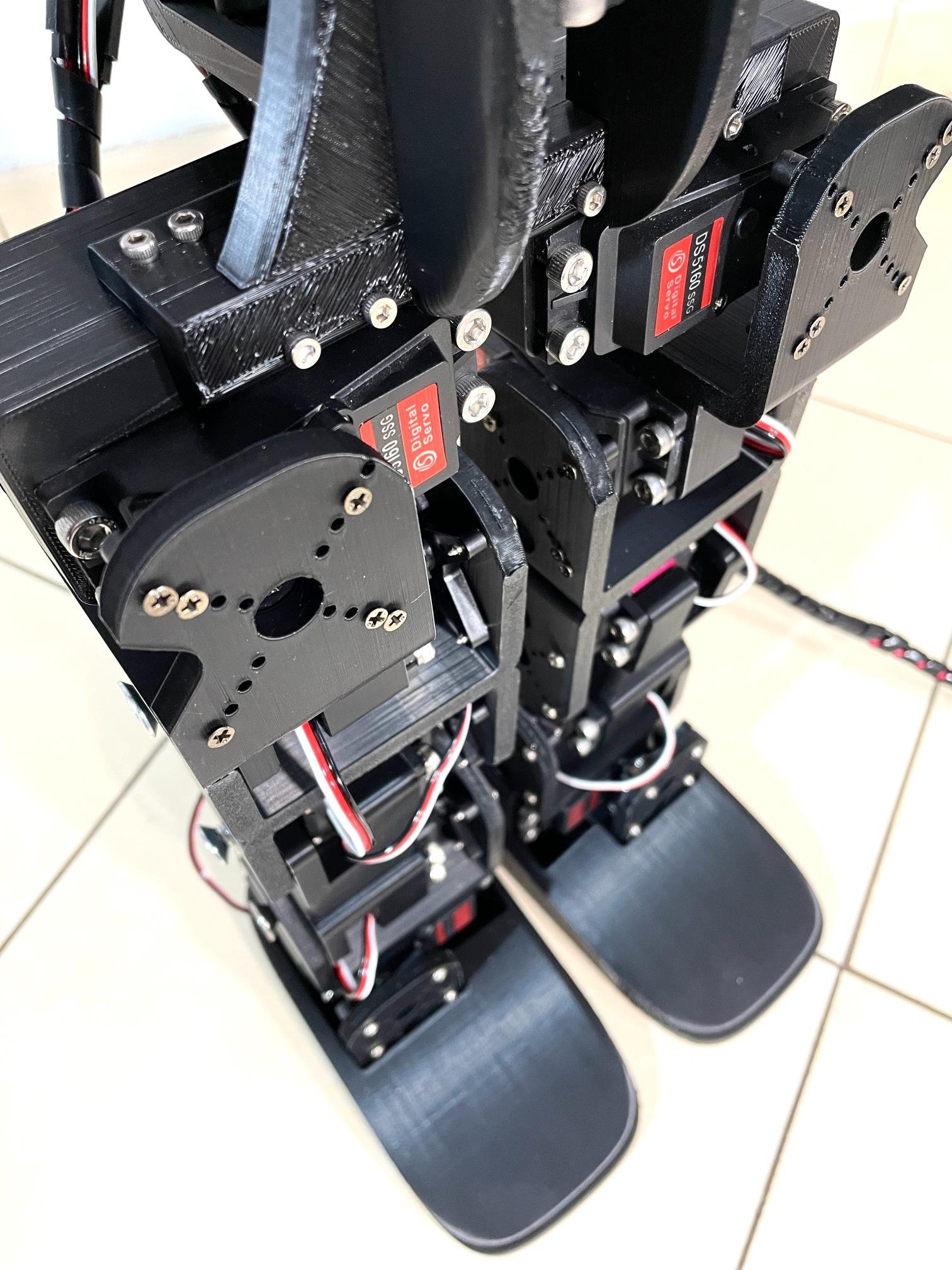

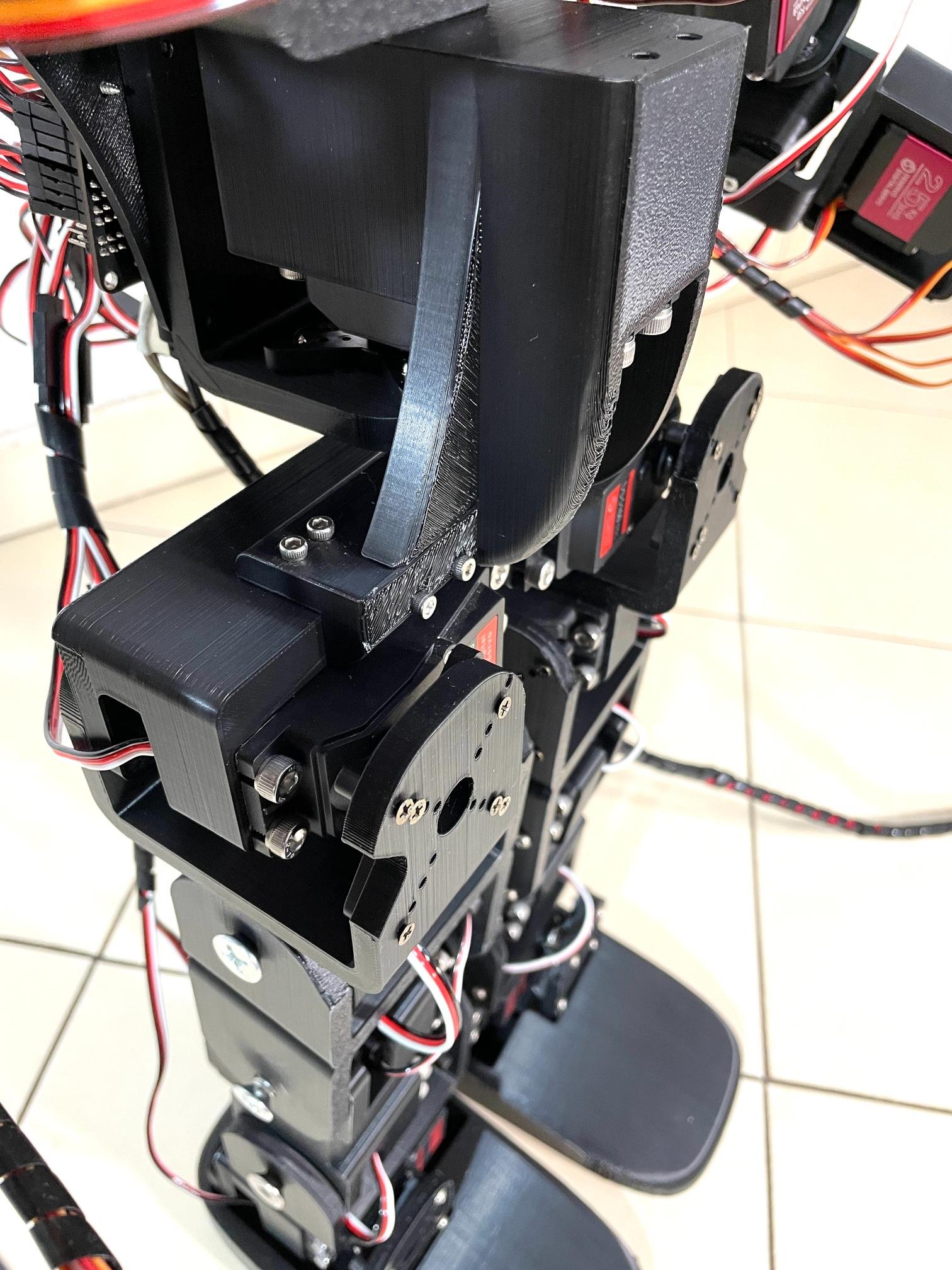

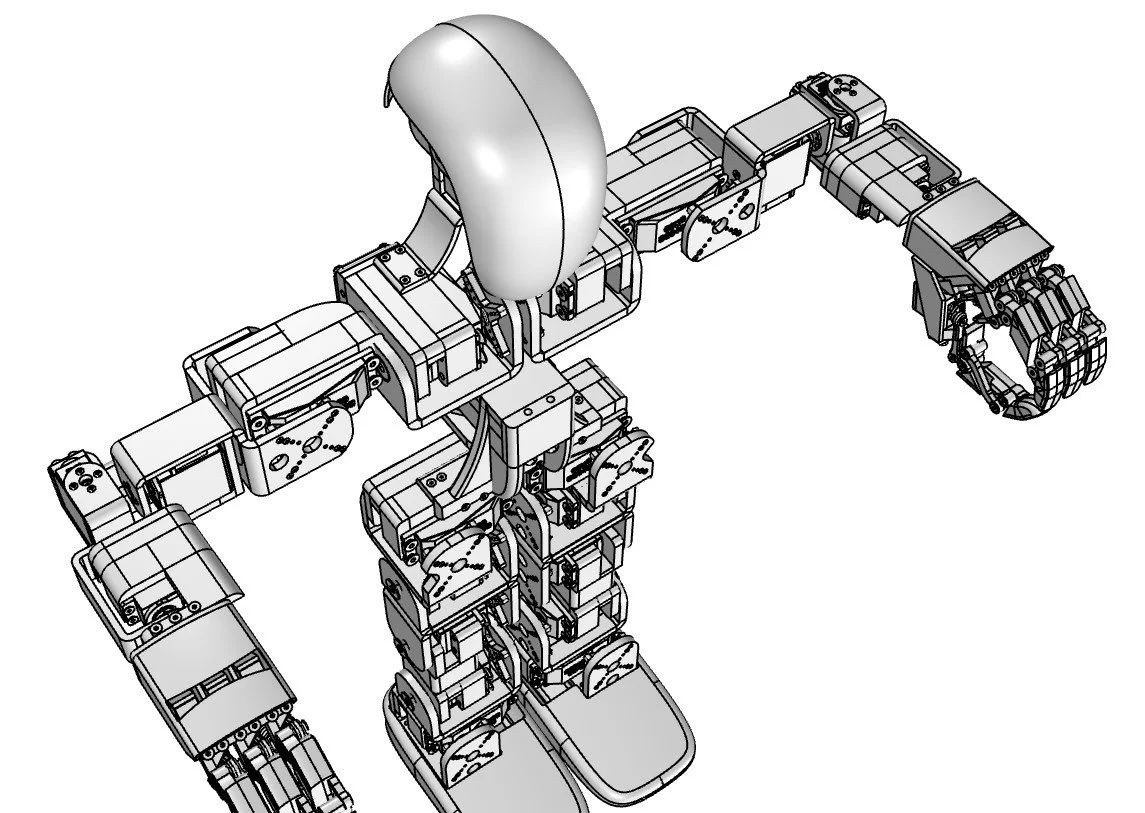

✅ Stronger and more stable structure for greater reliability

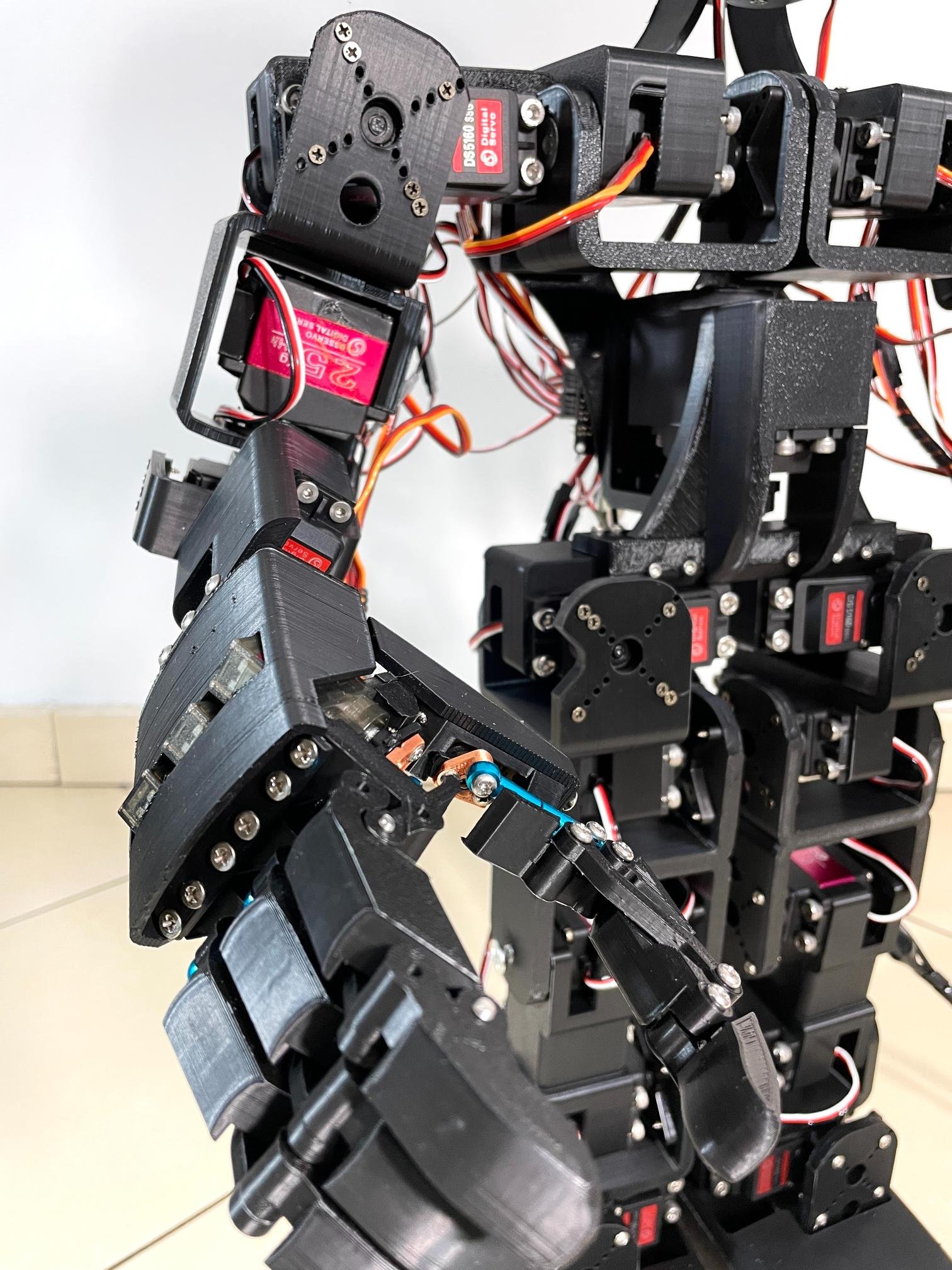

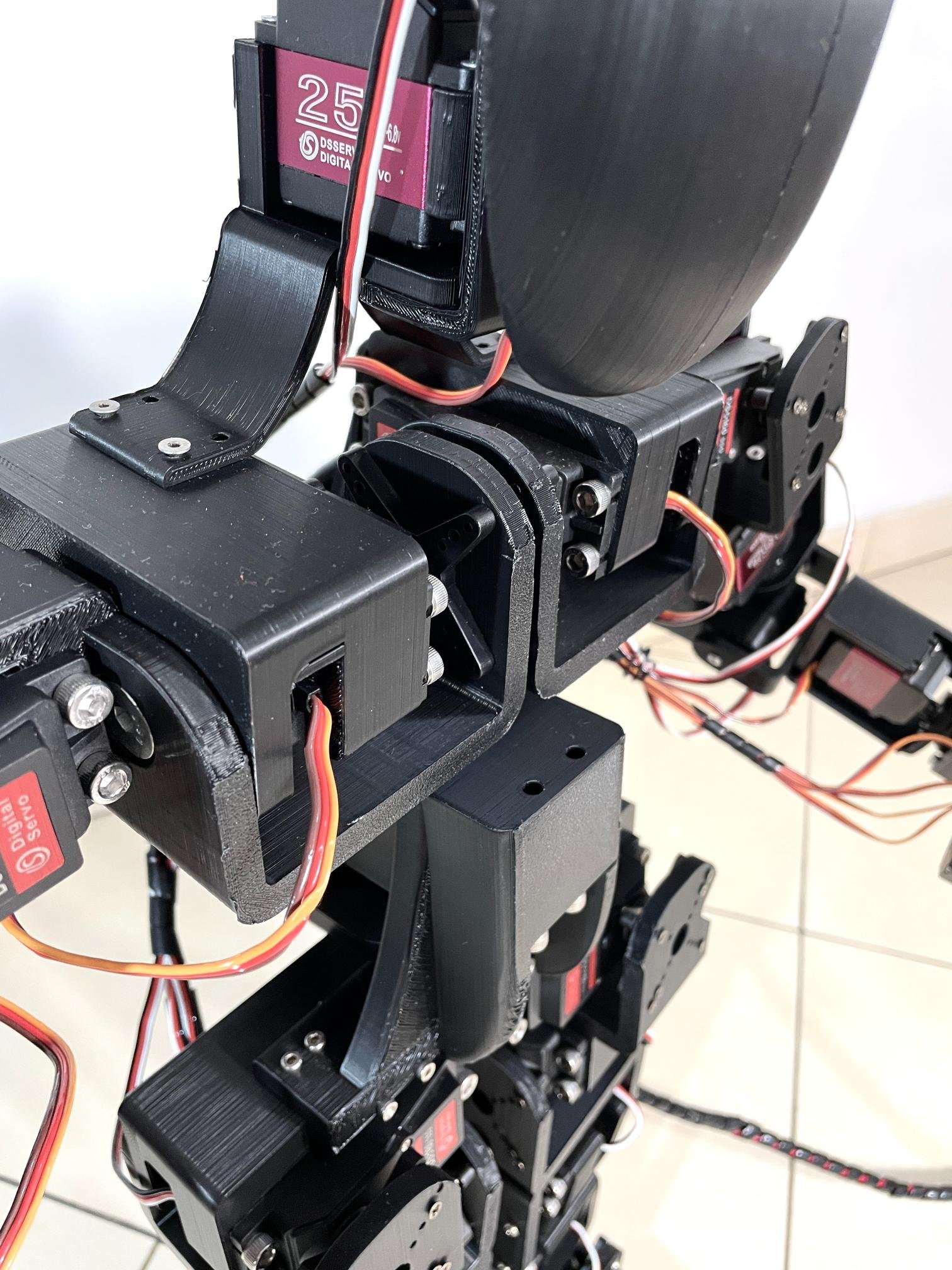

✅ Improved movements on arms, legs, and torso for greater versatility

✅ Integrated control on a single servo motor board for synchronized movements

✅ Simplified assembly and customization with 3D printed components

✅ Ability to develop custom applications and harness the power of our high-performance servomotors

YOUBIONIC X3 BASIC DOC

3D Printing Files

Assembly Diagrams

Customer Support

YOU WILL GET EVERYTHING BY E-MAIL 📩 AND YOU WILL HAVE ACCESS WHERE AND WHEN YOU LIKE

⚠️ LIMITED TIME OFFER ⚠️

Youbionic gives you 100% money-back guarantee on all purchase ⭐⭐⭐⭐⭐

YOUBIONIC X3 FULL DOC

3D Printing Files

Assembly Diagrams

3D Model Assembly

Servo Controller

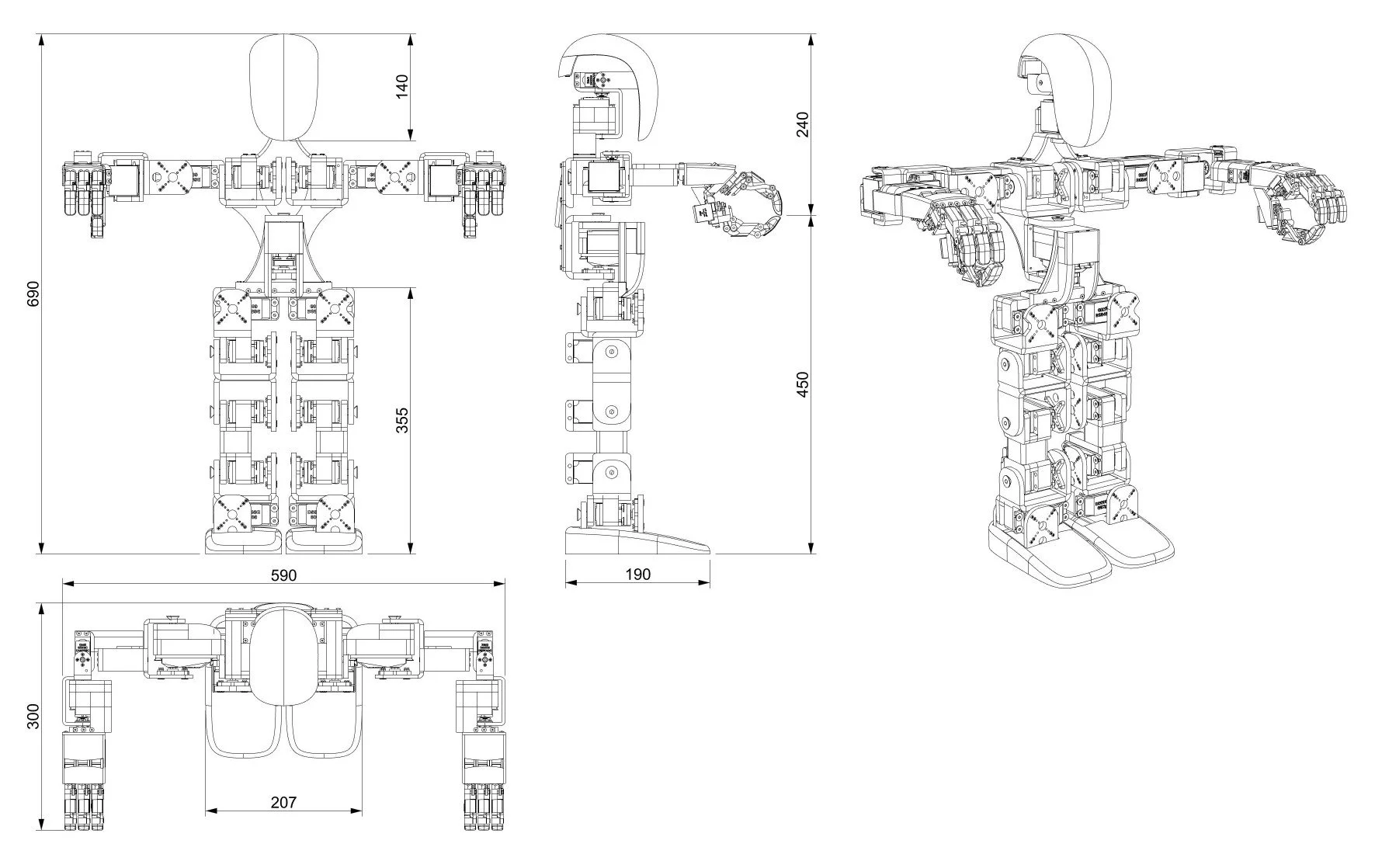

Technical Drawing

Videos and Photos

Customer Support

YOU WILL GET EVERYTHING BY E-MAIL 📩 AND YOU WILL HAVE ACCESS WHERE AND WHEN YOU LIKE

⚠️ LIMITED TIME OFFER ⚠️

Youbionic gives you 100% money-back guarantee on all purchase ⭐⭐⭐⭐⭐

👇CHEST COVER FREE DOWNLOAD👇

DISCOVER HOW YOUBIONIC X3 CAN RADICALLY TRANSFORM YOUR APPROACH TO ROBOTICS, OFFERING A RANGE OF BENEFITS FROM LEARNING AND SKILL DEVELOPMENT TO CAREER OPPORTUNITIES AND INNOVATION IN THE EMERGING FIELD OF ROBOTIC TECHNOLOGIES

✅ Learning: Gain practical knowledge in robotics and engineering.

✅ Cost savings: Save on purchasing costs and take advantage of low-cost components.

✅ Hands-on experience: Assemble and interact directly with robot components.

✅ Skill development: Improve your skills in programming, design, and engineering.

✅ Career opportunities: Open up new opportunities in robotics and emerging technologies.

✅ Innovation: Contribute to ongoing innovation in the robotics community.

YOUBIONIC X3

LIST OF SERVOMOTORS

ARMS:

🔘 X4 Servomotors DS5160

🔘 X6 Servomotors DS3225

HANDS:

🔘 X8 Servomotors MG90S

HEAD:

🔘 X2 Servomotors DS3225

LEGS:

🔘 X10 Servomotors DS5160

TORSO:

🔘 X1 Servomotor DS5160

-

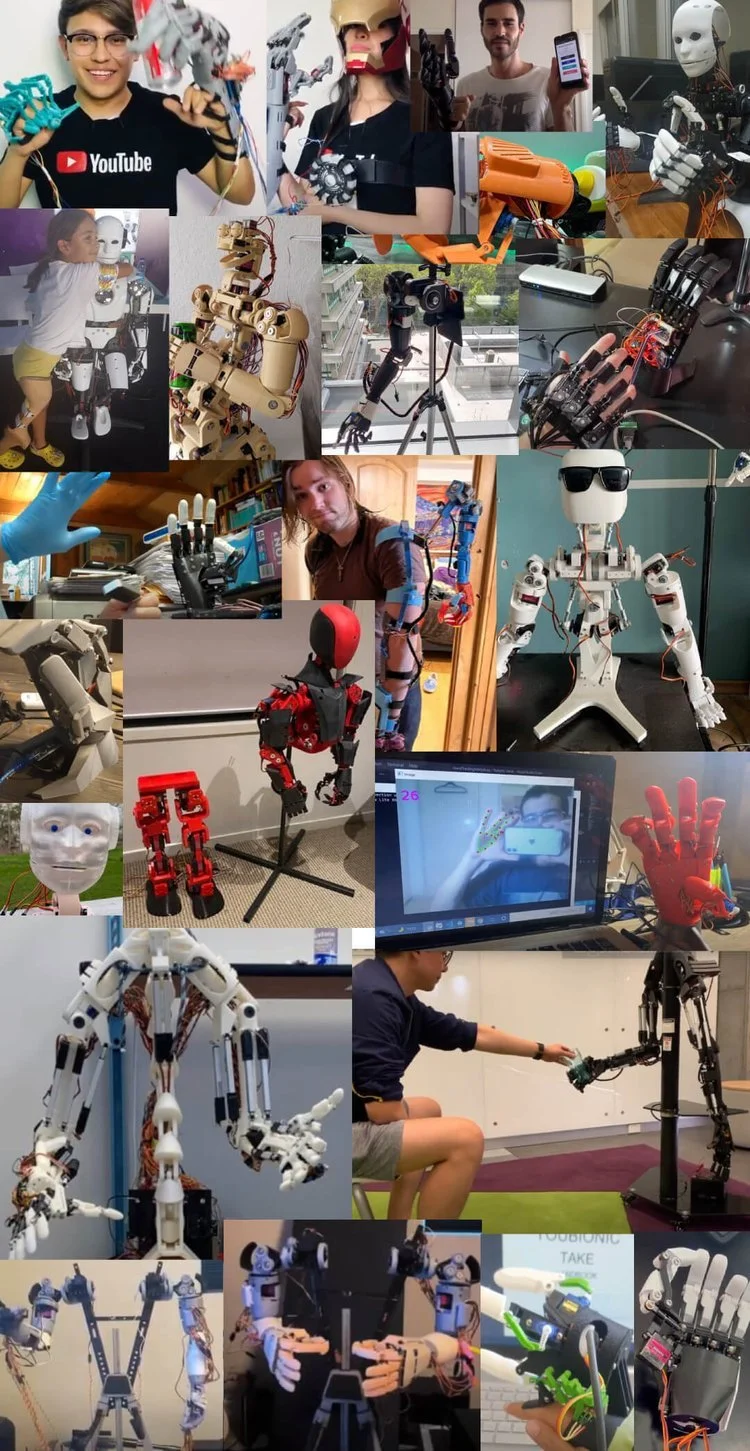

Youbionic was the jumpstart I needed to go from just dreaming about robotics to unlocking the skills and knowledge required to get started in one of the fastest growing fields today. The fact that Youbionic has made it so easy for anyone to start 3D printing and assembling a robot at home still blows my mind. If you do get stuck or have questions during your build that’s where Youbionic’s secret weapon comes in. The private telegram chat with the creators and other makers is one of the companies biggest strengths. Everyone there is learning along with you. You’ll find a truly diverse worldwide community of people learning from eachother as well as cheering eachother on in their endeavors.

-

As a STEM instructor for an urban charter school, I have a limited budget, but using Youbionic I can create working robots with my students for a minimal starting cost. As part of my program, I had students 3D print in one unit, connect circuits in another unit, and code microcontrollers in a third unit. I used to do all those separately, but with Youbonics I can do them all as one larger project. The directions are thorough and very easy to use, and just when I think I am done with my curriculum there is another great upgrade to the robots that my next class can work on an upgrade or a new advanced class or after-school program.

-

When I was developing a remote-controlled robot, I found this product’s design data and instructions very useful. I could easily make and customize my own robot. The eye-catching design was also effective.

-

After I got to know Youbionic's products and innovations, I started to follow them closely and with great satisfaction! I teach a class of 15 students and I teach Robotics using some items that we can buy. I would like to be able to buy all Youbionic products but unfortunately I don't have the financial conditions to buy the models for my students! Congratulations for your work!

-

I would recommend this product to any high school or collage that has robotics. This product can help people acheve great knowledge in robotics and also knowledge of different types of 3d printing. Hands down this is a great product and hope to see it grow. It has made me a better.